Gases, vapours, mists and dusts can all form explosive atmospheres with air. Hazardous area classifications are used to identify places where, because of the potential for an explosive atmosphere, special precautions over sources of ignition are needed to prevent fires and explosions.

There are various international bodies and directives that govern the classification of and precaution methods used in various explosion sensitive areas, some of which are -

● Appareils destinés à être utilisés en Atmosphères Explosivesis (ATEX, EU)

● National Electric Code (NEC, USA)

Hazardous area classification should be carried out as an integral part of the risk assessment to identify places (or areas) where controls over ignition sources are needed (hazardous places) and also those places where they are not (non hazardous places). Hazardous places are further classified in Zones which distinguish between places that have a high chance of an explosive atmosphere occurring and those places where an explosive atmosphere may only occur occasionally or in abnormal circumstances. The definitions of the Zones also recognise that the chance of a fire or explosion depends on the likelihood of an explosive atmosphere occurring at the same time as an ignition source becomes active.

There are various international bodies and directives that govern the classification of and precaution methods used in various explosion sensitive areas, some of which are -

● Appareils destinés à être utilisés en Atmosphères Explosivesis (ATEX, EU)

● National Electric Code (NEC, USA)

● International Electrotechnical Commission (IEC)

● Dangerous Substances and Explosive Atmospheres Regulations (DESAR, UK) Hazardous area classification should be carried out as an integral part of the risk assessment to identify places (or areas) where controls over ignition sources are needed (hazardous places) and also those places where they are not (non hazardous places). Hazardous places are further classified in Zones which distinguish between places that have a high chance of an explosive atmosphere occurring and those places where an explosive atmosphere may only occur occasionally or in abnormal circumstances. The definitions of the Zones also recognise that the chance of a fire or explosion depends on the likelihood of an explosive atmosphere occurring at the same time as an ignition source becomes active.

For example, if a dangerous substance is being carried through a seamless pipe, and that pipe has been properly installed and maintained, it is extremely unlikely that the substance will be released. An explosive atmosphere would not be expected to occur from this source and the area surrounding the pipe would be non-hazardous.

A spillage from a small bottle of solvent would release so little flammable material that no special precautions are needed other than the general control of ignition sources (for example, no smoking) and cleaning and disposing of the spillage. It would not be classified as a hazardous area. When considering whether hazardous area classification is necessary for “small” quantities of dangerous substances the actual circumstances of use and any specific industry guidance should also be taken into account.

Dangerous substances in small pre-packaged containers for sale, display, etc. in retail premises would not normally require the area to be classified as hazardous. However we would expect a hazardous area classification to be carried out for prepackaged containers held in large quantities e.g. in warehouses.

Classifying Hazardous Areas into Zones

Classifying Hazardous Areas into Zones

Once an area has been identified as hazardous it should be classified into zones based on the frequency and persistence of the potentially explosive atmosphere. This then determines the controls needed on potential sources of ignition that may be present or occur in that area. These controls apply particularly to the selection of fixed equipment that can create an ignition risk such as solenoid valves; but the same principles may be extended to control the use of mobile equipment and other sources of ignition that may be introduced into the area (for example, matches and lighters) and the risks from electrostatic discharges.

The directives define a place where an explosive atmosphere may occur in quantities that require special precautions to protect the health and safety of workers as hazardous. Classifications are dependent on the exposure of the area to explosive atmosphere or ignition points and may be continuous exposure, occasional exposure or unlikely to have exposure. A place where an explosive atmosphere is not expected to occur in quantities that require such special precautions is deemed to be non-hazardous.

The directives define a place where an explosive atmosphere may occur in quantities that require special precautions to protect the health and safety of workers as hazardous. Classifications are dependent on the exposure of the area to explosive atmosphere or ignition points and may be continuous exposure, occasional exposure or unlikely to have exposure. A place where an explosive atmosphere is not expected to occur in quantities that require such special precautions is deemed to be non-hazardous.

The term “not expected to occur in such quantities” means that employers should consider the likelihood of releases of explosive atmospheres as well as the potential quantity of such releases when considering area classification. So if a release is extremely unlikely to occur and/or if the quantities released are small, it may not be necessary to classify the area as hazardous. Site-specific factors should always be taken into account for such cases.

Gases, vapours and mists

For gases, vapours and mists the zone classifications are:

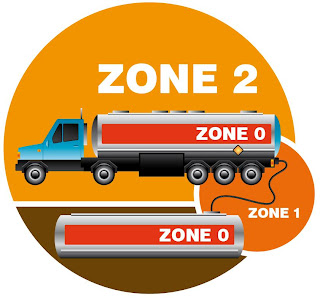

Zone 0: A place in which an explosive atmosphere consisting of a mixture with air of dangerous substances in the form of gas, vapour or mist is present continuously or for long periods or frequently.

Zone 1: A place in which an explosive atmosphere consisting of a mixture with air of dangerous substances in the form of gas, vapour or mist is likely to occur in normal operation occasionally.

Zone 2: A place in which an explosive atmosphere consisting of a mixture with air of dangerous substances in the form of gas, vapour or mist is not likely to occur in normal operation but, if it does occur, will persist for a short period only.

Dusts

For dusts the zone classifications are:

Zone 20: A place in which an explosive atmosphere in the form of a cloud of combustible dust in air is present continuously, or for long periods or frequently.

Zone 21: A place in which an explosive atmosphere in the form of a cloud of combustible dust in air is likely to occur in normal operation occasionally.

Zone 22: A place in which an explosive atmosphere in the form of a cloud of combustible dust in air is not likely to occur in normal operation but, if it does occur, will persist for a short period only.

Equipment Categories for Hazardous Areas

Equipment categories and zones

The hazardous area zone classification and corresponding equipment categories are:

Designed to prevent any means of ignition arisingEquipment Categories for Hazardous Areas

Special precautions need to be taken in hazardous areas to prevent equipment from being a source of ignition. In situations where an explosive atmosphere has a high likelihood of occurring, reliance is placed on using equipment with a low probability of creating a source of ignition. Where the likelihood of an explosive atmosphere occurring is reduced, equipment constructed to a less rigorous standard may be used. Equipment is categorised (1, 2 or 3) depending on the level of zone where it is intended to be used.

Equipment categories and zones

The hazardous area zone classification and corresponding equipment categories are:

Zone 0 or Zone 20 - category 1 equipment

Zone 1 or Zone 21 - category 2 equipment

Zone 2 or Zone 22 - category 3 equipment

Method of Explosion Protection

Zone 2 or Zone 22 - category 3 equipment

Method of Explosion Protection

- Increased Safety Protection

(e)

In

this method any components that produce sparks as part of their normal

operation are excluded from the equipment. Components are designed to substantially

reduce the likelihood of fault conditions that cause ignition. This is done by

reducing and controlling working temperatures, ensuring the electrical

connections are reliable, increasing insulation effectiveness, and reducing the

probability of contamination by dirt and moisture ingress.

- Non Sparking

Protection (nA)

Precautions

are taken with connections and wiring to increase reliability, though not to as

high a degree as for ‘e’. Where internal surfaces are hotter than the desired T

rating discussed later, they can be tightly enclosed to prevent the ready

access of a flammable atmosphere into the internal parts. This is the

"restricted breathing enclosure" method. The use of this method also means that high ingress protection ratings of IP65 and above are built into the design.

Designed to limit the

ignition energy of the circuit

- Intrinsic Safety

Protection (ia/ib)

In

this method the circuit parameters are reliably controlled to reduce potential

spark energy to below that which will ignite the ambient gas-air mixture. The

coding ‘ib’ and ‘ia’ denotes that the unit will not cause ignition of explosive

atmosphere under normal operation and with one and two faults present in the

circuitry respectively. This method does not protect entirely against the local

over-heating of damaged connections or conductors and these should be kept

sound and suitably protected against damage.

Designed to prevent

the flammable mixture reaching a means of ignition

- Oil immersion protection (o)

This is an old method mainly used with switchgear. Any spark

generated by the operation of the switchgear is formed under oil and the

venting is controlled.

- Pressurised protection (p)

There are two protection methods. One maintains a positive

static pressure inside the equipment. The other involves a continuous flow of

air or inert gas to neutralise or carry away any flammable mixture entering or

being formed within the enclosure. Essential to both methods are monitoring

systems and purging schedules.

- Encapsulation Protection (m)

In

this method the potentially incendive components are encapsulated so that the

flammable atmosphere is excluded. The method also involves the control of the

surface temperature under normal and fault conditions.

Designed to prevent

any ignition from spreading

- Flameproof Enclosure

Protection (d)

In

this method the potential incendive components are contained within an

enclosure. Although the flammable atmosphere can enter the enclosure, any

resulting explosion is contained and its transmission outside the enclosure

prevented.

- Powder Filling

Protection (q)

This

method involves the enclosure to be filled with an inert powder. The enclosure

is also vented. The method is primarily of use where the incendive action is

the abnormal release of electrical energy by the rupture of fuses or failure of

components such as capacitors.

Explosion Groups

Explosive gases, vapors and dusts have chemical properties that affect the likelihood and severity of an explosion. Such properties include flame temperature, minimum ignition energy, upper and lower explosive limits, and molecular weight. Every substance has a differing combination of properties but it is found that they can be ranked into similar ranges, simplifying the selection of equipment for hazardous areas.

Apparatus marked IIB can also be used for IIA gases. IIIC marked equipment can be used for both IIIA and IIIB. If a piece of equipment has just II and no A, B, or C after then it is suitable for any gas group.

Temperatures

Additional information relating to the process that involve the dangerous substances should also be taken into account, including the temperatures used in the process, as this will influence the nature and extent of any release, and the extent of any subsequent hazardous areas. Some substances do not form explosive atmospheres unless they are heated, and some liquids if released under pressure will form a fine mist that can explode even if there is insufficient vapour.

Temperatures

Additional information relating to the process that involve the dangerous substances should also be taken into account, including the temperatures used in the process, as this will influence the nature and extent of any release, and the extent of any subsequent hazardous areas. Some substances do not form explosive atmospheres unless they are heated, and some liquids if released under pressure will form a fine mist that can explode even if there is insufficient vapour.

Product Selection and Marking

Using the above information, products can be selected as per the requirement of the zone. An example of Electrical Equipment designation is given below for ATEX and IEC methods of classification.

Risk Assessment

Identifying hazardous or non-hazardous areas should be carried out in a systematic way. Risk assessment should be used to determine if hazardous areas exist and to then assign zones to those areas. The assessment should consider such matters as:

- the hazardous properties of the dangerous substances involved;

- the amount of dangerous substances involved;

- the work processes, and their interactions, including any cleaning, repair or maintenance activities that will be carried out;

- the temperatures and pressures at which the dangerous substances will be handled;

- the containment system and controls provided to prevent liquids, gases, vapours or dusts escaping into the general atmosphere of the workplace;

- any explosive atmosphere formed within an enclosed plant or storage vessel; and,

- any measures provided to ensure that any explosive atmosphere does not persist for an extended time, e.g. ventilation.

Taken together these factors are the starting point for hazardous area classification, and should allow for the identification of any zoned areas.

No comments:

Post a Comment