|

| Deciding between a loud system and a leaky one when decompression is involved need not be as hard as you think.

|

A lot of the time, we get

complaints from press manufacturers that come to us with the following problem:

"I have a cylinder on my

press and every time I have to unload it, there is a loud banging sound."

If we consider that all the

other mechanical parts of the press are working fine (i.e. the problem lies

with the hydraulics), it is most likely caused by the uncontrolled decompression

of the hydraulic fluid. The problem arises because hydraulic fluid is not

perfectly rigid.

One of the popular

misconceptions with hydraulics today is that fluids are incompressible within

systems. The fact is that they are compressible, albeit the compressibility is

not as large as in the case of gasses. The ratio of a fluid's decrease in

volume as a result of increase in pressure is given by its bulk modulus of

elasticity. The bulk modulus for most hydraulic fluids is approximately 17,000

kg/cm2 which results in a volume change of around 0.4% per 70 bar (1000 psi).

When the change in volume exceeds 160 cc, decompression must be controlled.

The compression of hydraulic

fluid results in storage of energy, similar to the potential energy stored in a

compressed spring. Like a compressed spring, compressed fluid has the ability

to do work. If decompression is not controlled, the stored energy dissipates

instantaneously. This sudden release of energy accelerates the fluid, which

does work on anything in its path. Uncontrolled decompression stresses

hydraulic hoses, pipes and fittings, creates noise and can cause pressure

transients that damage hydraulic components. This is similar to a balloon burst

by means of a pin when the compressed air is opened to atmosphere rather than

allowing the air to be let out smoothly.

|

Figure 1:Successive

loading of a cylinder leads

to a pressure rise

in the fluid contained within. |

Consider a system as shown in Figure 1 below. The cylinder bore is 100 cm² and the height is 10 cm.If we load the cylinder with a 7000 Kg weight the height which was 10 cm initially will now become 9.9 cm. Thus there is a volume reduction of 1% (or 10cc). Here an assumption is made that the system is not perfectly rigid i.e. cylinder diameter does change. Add another 7000 Kg and the height will reduce to 9.81 cm, and another 7000 Kg would make it approx 9.712 cm and so on. Thus increase in weight would reduce the volume.

Similarly if we started with 21000 kg of weight on a closed cylinder with 100cm sq area and 10 cm height, and we remove 7000 Kg weight, the height would increase to 10.1 cm. remove another 7000 Kg and the height would be about 10.2, remove another 7000 Kg and the height would be about 10.3 cm.

Note: The relationship between the pressure and the volume is not linear here but exponential. Adding 7000 bar of pressure will not compress the fluid to zero volume.

|

Figure 2: An enclosed fluid being pressurised

will

develop potential energy similar to that of a compressed

spring. This

energy is then released instantaneously as

noise and vibrations when the fluid

is decompressed

|

Now we take another example

shown in Figure 2 below. We have an enclosed chamber of volume 100 cc in which

a pump is pumping oil. The Relief Valve is set at 350

bar and as soon as the pressure in the system reaches 350 bar, we would find

the pump blowing over the Relief valve. If the pump is shut off, the Check

valve will hold the pressure in the tank at 350 bar. In order to lower the

pressure all that is needed to be done is to open the Shut Off valve. How much

oil should come out of this valve? If we remove 1cc of oil, the pressure would

drop to 280 bar; another removal of approx 1cc would bring it to 210 bar;

another removal of approx 3cc will bring it to zero pressure. This phenomenon

is what is used in decompression circuits.

The fluid needs to be removed

gradually. If the shut off valve is opened suddenly, the fluid will be exposed

to atmospheric pressure and approx 5cc of oil (the amount required to bring the

oil to atmospheric pressure) will escape making a big noise and the chatter of

system.

There are two popular methods used to achieve decompression of a

circuit.

1. Using a Pilot Operated Check valve with an inbuilt decompression

feature (Figure 3).

2. Using a poppet type decompression valve for allowing few ccs

of oil to escape followed by the main opening of the pilot check valve holding

the load in place

|

| Figure 3: Pilot Check Valves with in-built decompression feature. |

|

Figure 4: Decompression

using PO Check with

internal decompression

feature |

Use of a Pilot Operated Check

valve with decompression feature has its advantages. It gives a compact system

and a cheap one (Figure 4). However, the decompression feature in a Pilot

Operated check valve increases the area ratio of the valve. A standard Pilot

Check valve has an area ratio between 3 and 4 (5 in extreme cases). Thus a 300

bar system will open between 75-100 bar. Use of the decompression type Pilot

Check valve increases the area ratio to about 20 (25 in some cases). Therefore

a 300 bar system fitted with Decompression Pilot Check with area ratio of 25

will open at 12 bar and that with area ratio of 20 will open at 15 bar. This

will reduce the loud bang in the system which occurs when an un-decompressed

Pilot Check valve opens and the system will become smoother. This looks

perfectly fine and is acceptable to customers.

Now take the same system when

it is set to 100 bar (as in the case of many pressing applications). The same

decompression type Pilot Check valve (with area ratio between 20 to 25) will

open the valve between 4-5 bar. The standard pressure drop across a moderately

clogged filter is 2 bar which an excessively clogged filter may issue pressure

drops of even 4 bar.

This is notwithstanding the various other pressure drops

caused due to hydraulic fittings such as elbows, contaminants in the pipe

and/or other unwanted resistances to flow in the tank line. Thus one tends to

think that there is some problem with Pilot Check valve, ignoring the fact that

the problem lies with the circuit design. These systems will work only when the

system pressure is always 250 bar+.

|

| Figure 5: Isolated

Holding and Decompressing circuits |

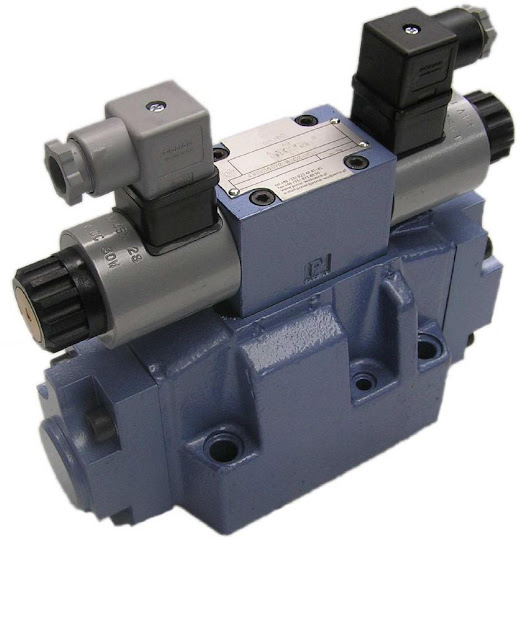

The solution to the above

problem is to isolate the Decompression system from the Pilot Check system

using a solenoid valve as shown in Figure 5. Along with the solenoid valve, an

orifice of size 0.8 to 1.6 mm is used as well. The potential energy of the

compressed fluid is converted into heat by metering the compressed volume of

fluid across the orifice. The solenoid valve is a poppet type valve with metal

on metal contacts that ensure that the valve has zero leakages. The valve opens

before the main stage DC valve and releases a few drops of oil. This ensures

that the cylinder pressure is near zero when the main solenoid valve opens.

This allows the Pilot Operated Check (with standard pilot ratios from 3 to 4)

to operate without any noise or vibration problems. This system, albeit costly,

works well through all pressure ranges; whether in a high pressure system of

300 bar or a low pressure one of 100 bar.

Tucson offers various types of decompression solenoids in

either a line mounting or a subplate mounting. Tucson

recommends a DC solenoid as this has a longer life over its AC counterpart.

This is due to the rectifier plug embedded on the solenoid coil could get

damaged if there is a voltage spike. The solenoids in Tucson

are offered in 12V and 24V DC and 230V AC. Many major press manufacturing units

have changed over from a decompression Pilot Check Valve to multi stage

Solenoid Decompression valves, which are only a shade more expensive but

reliable, accurate and long lasting.