Application:

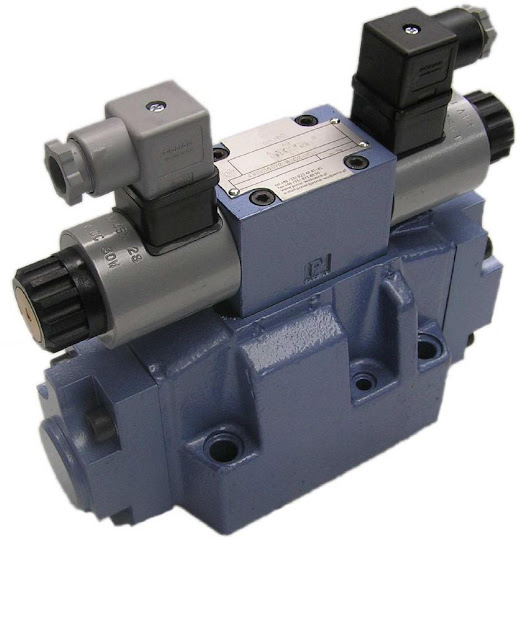

Directional spool valves type WEH16 electro-hydraulically operated are intended for change in direction of fluid flow in a system and thus it allows to change direction of movement of a receiver - mostly piston rod of a cylinder or hydraulic motor as well to use functions: on and off. These directional spool valves are used for subplate mounting in any position in a hydraulic system. The directional spool valve type WEH16 is complied with the regulations of directive 2006/95/WE for the following voltages:

•50 – 250 V for AC

•75 – 250 V for DC

Operation:

The main bore and annular ports P, T, A, B are made in the housing (1) and connected to its subplate connection. The directional valve is switched by shifting the spool (2) into any one end position. Various control functions are dependent on the spool which affects the change in

configuration of connections among ports P, T, A, B in the housing. The spool is shifted from its neutral position by affecting pressure of hydraulic fluid supplied via pilot valve (4) into one of the chamber of the caps (3). The pilot valve – type WE6…12/… is operated by means of solenoids (5). In case of failure, the pilot valve (4) may be shifted manually by means of manual overrides (6) – version …4WEH16…/…N. The spool is centered in the neutral position by means of springs (7) or may be hydraulically operated by the fluid pressure from the pilot valve. For 3-position directional valves the centering is possible by means of a sleeve (8). Sealing of the directional valve to the subplate is secured by sealing rings.

Specifications:

Flow

|

Up to 240 lpm

|

Maximum Operation Pressure

|

Port P, A, B – 350 bar

Port T – 250 bar

|

Switching Pressure

| 4WEH16 - 4.5 bar H-4WEH16.../...D1... 7 bar |

Weight

|

max 10,5 kg

|

Supply Voltage

|

12VDC, 24VDC, 230VAC

|

Power Requirement

|

30 W

|

Hydraulic Fluid

|

Mineral Oil

|

For more information:

No comments:

Post a Comment